Mastering the Art of Color Case Hardening: A Definitive Guide

Color case hardening is a fascinating metallurgical process that imparts both stunning aesthetics and enhanced durability to ferrous metals, particularly steel. This guide provides a comprehensive exploration of the color case hardening process, delving into the recipes, techniques, and underlying principles that create these captivating finishes. Whether you are a seasoned gunsmith, a metalworking enthusiast, or simply curious about this unique art form, this resource will equip you with the knowledge and understanding to appreciate and potentially replicate this beautiful and functional treatment. This is your comprehensive guide to color case hardening recipes and the process behind them.

Understanding the Essence of Color Case Hardening

Color case hardening is not merely a surface treatment; it’s a carefully controlled process that alters the chemical composition of the steel’s outer layer while simultaneously creating vibrant colors. Unlike simple coatings, this process diffuses carbon and nitrogen into the steel’s surface, creating a thin, hardened ‘case’ that is significantly more wear-resistant than the underlying core. The colors, ranging from straw yellows and blues to deep purples and browns, are a result of varying oxide thicknesses formed during the quenching stage. These colors are not simply aesthetic; they are indicators of the steel’s temper and the depth of the hardened case.

The process relies on a delicate balance of temperature, time, and atmospheric control. The steel is packed in a sealed container with a carbon-rich material, heated to a specific temperature, and then rapidly quenched. The quenching process is critical, as it determines the final hardness and the intensity of the colors. The skill lies in controlling these variables to achieve the desired aesthetic and functional properties.

The Science Behind the Colors

The vibrant colors seen on color case hardened steel are a result of thin-film interference. When light strikes the surface of the steel, some of it is reflected off the top of the oxide layer, while some penetrates the layer and is reflected off the steel beneath. The difference in the path lengths of these two reflected waves causes interference, which can either amplify or cancel out certain wavelengths of light. The resulting color depends on the thickness of the oxide layer. Different temperatures and quenching mediums create different oxide thicknesses, resulting in a spectrum of colors.

Essential Components: The Color Case Hardening Recipe

A successful color case hardening recipe involves several key elements, each playing a crucial role in the final outcome. These elements include the packing material, the heating process, and the quenching medium. Each component needs to be carefully selected and controlled to achieve the desired results.

- Packing Material: This is the source of carbon and nitrogen that diffuses into the steel’s surface. Common materials include bone charcoal, leather scraps, wood charcoal, and proprietary mixtures. The composition of the packing material influences the case depth and the resulting colors.

- Heating Process: The steel is heated in a furnace to a specific temperature, typically between 1350°F and 1500°F (730°C and 815°C). The temperature and duration of heating affect the case depth and the diffusion of carbon and nitrogen.

- Quenching Medium: The rapid cooling of the steel in a quenching medium is critical for hardening the case and creating the colors. Water, oil, and brine are common quenching mediums, each producing different colors and hardness levels.

Detailed Look at Packing Materials

The packing material is arguably the most critical component of the color case hardening recipe. It provides the carbon and nitrogen that diffuse into the steel’s surface, creating the hardened case. The type of packing material used will influence the case depth, the resulting colors, and the overall durability of the finish.

Bone Charcoal: This is a traditional and widely used packing material. It is produced by heating animal bones in the absence of oxygen, resulting in a porous, carbon-rich material. Bone charcoal produces vibrant colors and a relatively shallow case depth.

Leather Scraps: Leather scraps, particularly those from tanned leather, are another source of carbon and nitrogen. They tend to produce deeper case depths than bone charcoal and can create unique color patterns.

Wood Charcoal: Wood charcoal is less commonly used than bone charcoal or leather scraps, but it can still be effective. It generally produces a shallower case depth and less vibrant colors.

Proprietary Mixtures: Several companies offer proprietary packing mixtures specifically designed for color case hardening. These mixtures often contain a blend of different carbon and nitrogen sources, as well as additives that enhance color development and case hardening.

The Critical Role of Temperature Control

Precise temperature control is paramount in color case hardening. The temperature determines the rate of carbon and nitrogen diffusion, the depth of the hardened case, and the resulting colors. Insufficient heat will result in a shallow case and weak colors, while excessive heat can damage the steel.

The ideal temperature range for color case hardening is typically between 1350°F and 1500°F (730°C and 815°C). However, the exact temperature will depend on the type of steel, the packing material, and the desired case depth. It is crucial to use a reliable temperature control system and to monitor the temperature throughout the heating process.

Achieving Uniform Heating

Uniform heating is essential for consistent results. If the steel is heated unevenly, the case depth and colors will vary across the surface. To ensure uniform heating, the steel should be placed in the center of the furnace and surrounded by packing material. The furnace should also be properly calibrated and maintained to ensure consistent temperature distribution.

Quenching: The Art of Rapid Cooling

Quenching is the rapid cooling of the steel after it has been heated. This process is critical for hardening the case and creating the colors. The quenching medium, the temperature of the quenching medium, and the speed of quenching all influence the final outcome.

Water: Water is a common quenching medium for color case hardening. It produces rapid cooling and vibrant colors. However, it can also cause distortion or cracking in some steels.

Oil: Oil is a slower quenching medium than water. It produces less vibrant colors but is less likely to cause distortion or cracking. Oil quenching is often used for steels that are more prone to cracking.

Brine: Brine is a solution of salt and water. It produces very rapid cooling and intense colors. However, it is also more likely to cause distortion or cracking than water or oil.

Quenching Techniques

The quenching technique also plays a role in the final outcome. The steel should be quenched as quickly as possible after it is removed from the furnace. It should be fully immersed in the quenching medium and agitated to ensure uniform cooling. Some practitioners use specialized quenching fixtures to control the cooling process and minimize distortion.

Safety Precautions: Handling the Process Responsibly

Color case hardening involves high temperatures, potentially hazardous materials, and rapid cooling processes. It is imperative to prioritize safety at every stage. Appropriate personal protective equipment (PPE) is essential, including:

- Heat-resistant gloves: Protect hands from burns when handling hot steel and furnace components.

- Eye protection: Safety glasses or a face shield are crucial to guard against splashes of hot quenching liquids or flying debris.

- Respirator: When working with packing materials, especially bone charcoal, a respirator can prevent inhalation of dust and fumes.

- Apron or protective clothing: Shields against spills and splashes of hot liquids.

Work in a well-ventilated area to avoid inhaling fumes from the furnace or quenching process. Keep a fire extinguisher readily accessible. Always follow the manufacturer’s instructions for any equipment or materials used.

Color Case Hardening vs. Other Hardening Methods

While color case hardening enhances surface hardness, it’s important to distinguish it from other hardening methods like through-hardening or nitriding. Through-hardening involves heating the entire piece of steel to a critical temperature followed by quenching, resulting in uniform hardness throughout. Nitriding is a surface hardening process that introduces nitrogen into the steel, creating a very hard and wear-resistant layer, but without the color effects of case hardening. Color case hardening offers a unique combination of aesthetic appeal and improved surface durability, making it suitable for applications where both are desired.

Examples of Color Case Hardening in Action

Color case hardening has been used for centuries on a wide range of products, from firearms to tools to decorative items. Some notable examples include:

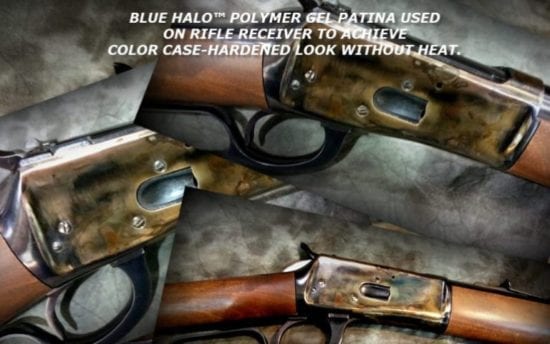

- Firearms: Color case hardening is commonly used on the receivers, hammers, and triggers of firearms. It provides both aesthetic appeal and improved wear resistance.

- Knives: High-end knives often feature color case hardened bolsters or guards. The process adds a touch of elegance and enhances durability.

- Tools: Certain hand tools, such as wrenches and pliers, may be color case hardened for improved wear resistance and a distinctive appearance.

- Decorative Items: Color case hardening can be used to create unique and beautiful finishes on decorative items, such as buckles, jewelry, and sculptures.

Advanced Techniques and Considerations

Beyond the basic recipe, several advanced techniques can be used to further refine the color case hardening process. These techniques include:

- Selective Case Hardening: This involves masking certain areas of the steel to prevent them from being hardened. This can be used to create patterns or to maintain the softness of certain areas.

- Double Quenching: This involves quenching the steel twice to enhance the colors or to achieve a specific hardness level.

- Tempering: Tempering is a heat treatment process that is used to reduce the brittleness of the hardened steel. It involves heating the steel to a lower temperature after quenching.

Troubleshooting Common Issues

Even with careful attention to detail, problems can arise during color case hardening. Here are some common issues and potential solutions:

- Weak Colors: This can be caused by insufficient heating, improper packing material, or a contaminated quenching medium. Ensure the steel is heated to the correct temperature for the appropriate duration, use fresh packing material, and clean the quenching medium.

- Uneven Colors: This can be caused by uneven heating or uneven quenching. Ensure the steel is heated uniformly and quenched rapidly and evenly.

- Distortion or Cracking: This can be caused by rapid quenching or by using a steel that is not suitable for color case hardening. Use a slower quenching medium or select a steel that is less prone to cracking.

A Legacy of Craftsmanship

Color case hardening is more than just a metallurgical process; it’s an art form that combines scientific principles with skilled craftsmanship. The captivating colors and enhanced durability it provides have made it a favorite among gunsmiths, knife makers, and artisans for centuries. By understanding the underlying principles and mastering the techniques, you can appreciate the beauty and functionality of this unique treatment.

Embracing the Art: Next Steps in Your Color Case Hardening Journey

The journey into color case hardening is a continuous learning process. There are numerous resources available to further your understanding, including books, articles, and online forums dedicated to metalworking and gunsmithing. Experimenting with different recipes and techniques is essential for developing your own unique style and achieving the desired results. Consider connecting with experienced practitioners who can provide guidance and share their expertise. The knowledge you’ve gained here provides a solid foundation for exploring this captivating art form and appreciating the fusion of science and artistry that defines color case hardening. Share your experiences with color case hardening in the comments below.